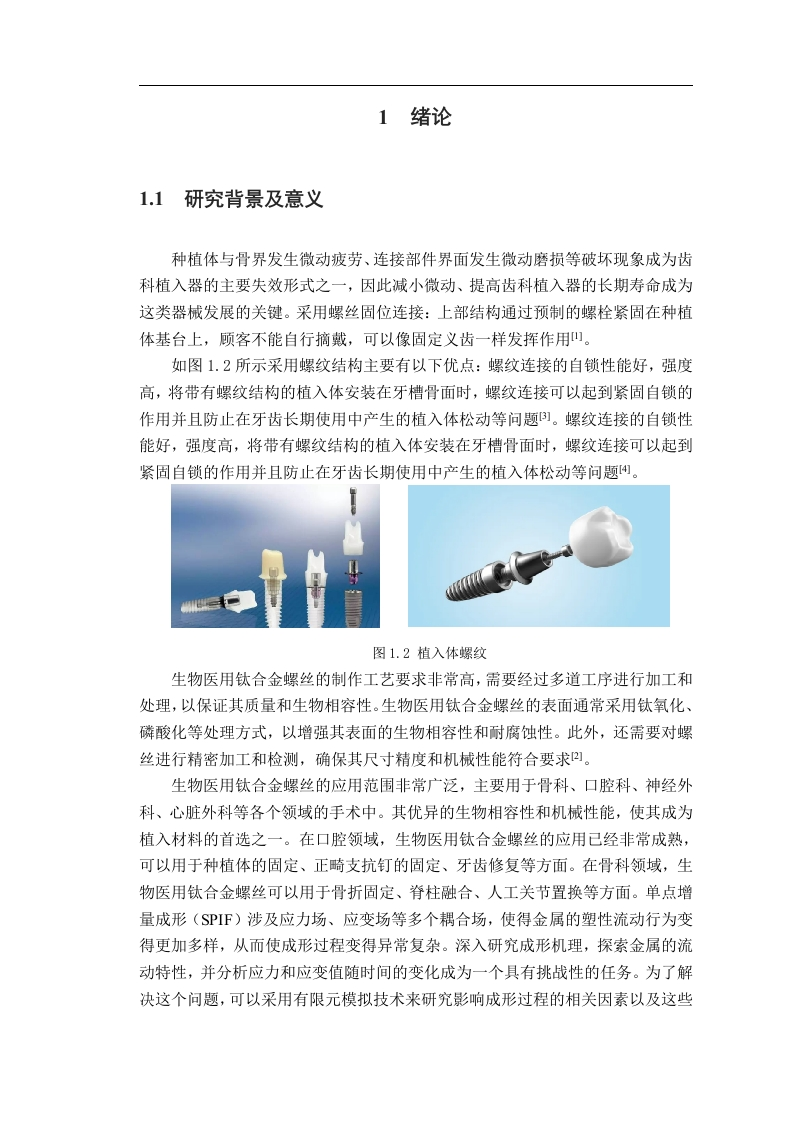

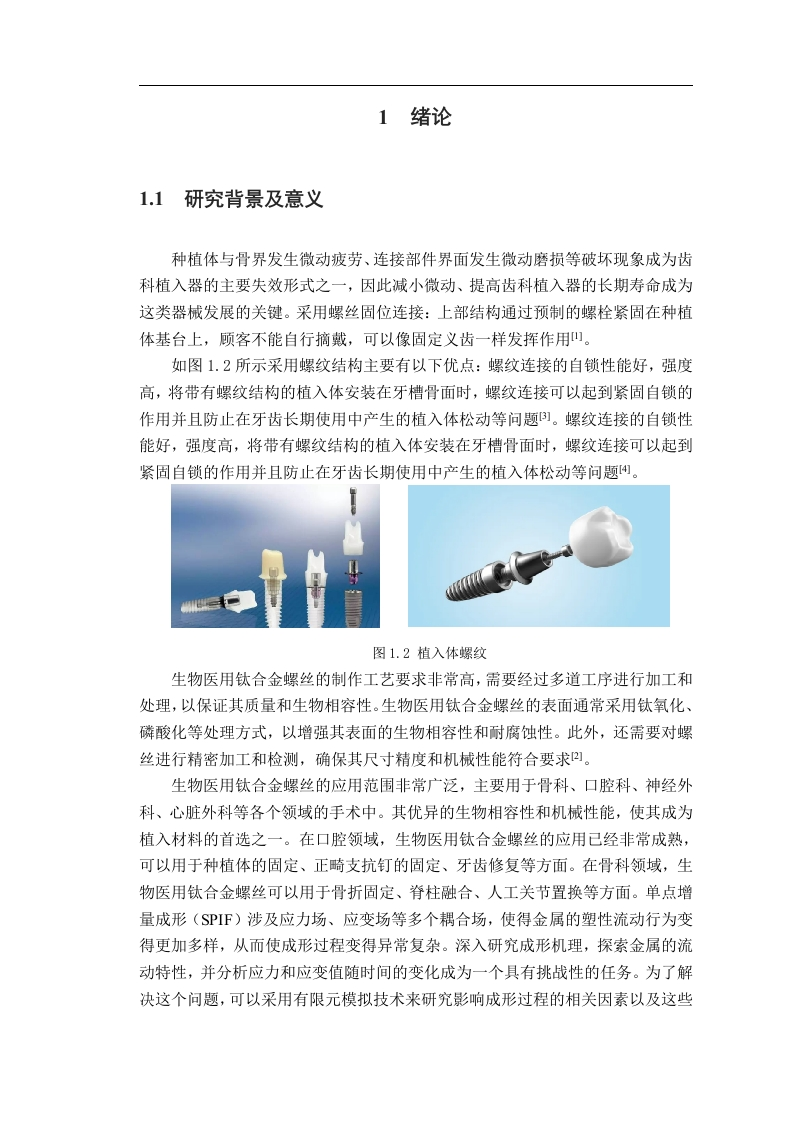

摘要随着时代的进步和科学技术的水平的提高,医疗器械行业得到快速发展,螺纹结构在齿科植入器械方面发挥着至关重要的作用。传统的螺纹冷滚打成形过程参数优化大多采用试错法,依赖个人经验进行模具设计和工艺摸索,不仅耗时耗力,而且试验效率和经济价值极低。针对螺纹冷滚打成形过程有限元模型进行研究已经越来越受到人们的广泛关注,提高了人们的重视程度。因此,建立螺纹滚压有限元模型,能够从应力-应变、滚丝轮最大成形力及最大成形扭矩等多角度深入理解螺纹冷滚打成形过程中金属塑性流动规律,本文通过使用ABAQUS有限元软件,模拟螺纹加工的过程。通过查阅有关冷滚打螺纹结构的相关文献,确定滚打轮,模芯,植入体尺寸以及植入体毛坯参数的设定,使用ABAQUS有限元仿真软件建立模型。从而对仿真后的结果进行分析,确定了滚打轮在不同深度时击打出的螺纹结构,对等效塑性应变图和变形里产生的影响。关键词:螺纹结构:冷滚打成形技术;有限元仿真:ABAQUSAbstractWith the progress of The Times and the improvement of the level of science andtechnology,the medical device industry has developed rapidly,and the threadstructure plays a vital role in dental implantation devices.The traditional parameteroptimization of thread cold roll forming process mostly adopts trial and error method,relying on personal experience for mold design and process exploration,which is notonly time and force consuming,but also has very low test efficiency and economicvalue.The research on the finite element model of thread cold rolling forming processhas attracted more and more attention.Therefore,the establishment of thread rollingfinite element model can deeply understand the metal plastic flow law in the processof cold rolling from the perspectives of stress-strain,maximum forming force ofrolling wheel and maximum forming torque,etc.This paper,simulates the process ofthread processing by using ABAQUS finite element software.By reviewing the relevant literature on cold rolling thread structure,the rollingwheel,die core,implant size and implant blank parameters were determined,and themodel was established using ABAQUS finite element simulation software.Thus,thethread structure of the rolling wheel and the influence on the equivalent plastic straindiagram and deformation.Key words:threaded structure;cold roll forming technology;finite elementsimulation;ABAQUS目录摘要Abstract...1绪论…1.1研究背景及意义1.2国内外水平及发展状况.21.2.1国外发展水平….21.2.2国内发展水平.22螺纹冷滚打成形原理研究.52.1螺纹冷滚打成形的原理52.2冷滚打螺纹的特点…。52.3三角螺纹冷滚打毛坯直径计算.62.4螺纹冷滚打的运动分析.72.5本章小结.83模型的建立.93.1有限元分析原理及特点..93.2设计仿真试验….93.3 ABAQUS有限元仿真流程.103.4滚打轮和植入体的模型建立103.5植入体对应参数值的设置.133.6植入体网格划分.143.7求解器的设定..163.8编辑相互作用…。173.9创建载荷相关属性.183.10编辑提交作业并运行计算.193.11可视化.…...203.12本章小结.214螺纹冷滚打仿真结果后处理分析224.1螺纹齿槽轮廓形态224.2螺纹冷滚打成形的应力分析24

暂无评论内容