摘要随着国家大力发展货运挂车的甩挂运输、统一配送的先进物流组织模式,实现降低运输成本、提高运输效率、节省能源、减少排放的目的,作为实现甩挂运输的关键零部件之一,半挂车支承装置能否安全、可靠、省力、快速地发挥作用是实现甩挂运输的重要因素。半挂车支撑腿即是半挂车支承装置,是安装于半挂货车车架前端左右两侧,用以实现牵引车与半挂车脱挂和接挂,并保证半挂车在与牵引车脱挂后能够独立保持稳定的装置,是半挂货车重要的零部件之一。采用齿轮机构为动力通过手把完成半挂车支承装置的升降。选择适合的结构形式画出支撑腿总装图,选择适合的方案画出相关零件的工程图,根据所画的支撑腿总装图和零件工程图对其进行计算和校核。该设计有效决解了半挂车支腿使用费时、费力、支撑稳定性差的问题,保证系统安全可靠,功能和工作原理明确、结构简单。简化结构,降低成本。半挂车可靠性高,便于维护。关键词:齿轮机构:半挂车:支撑腿总装图:零件图AbstractAs the country to develop freight trailer swing hang transport,unified distributionof advanced logistics organization mode,to reduce transportation costs,improve theefficiency of transportation,save energy,reduce emissions,as one of the key parts torealize swing hang transport,semi-trailer supporting device can safe,reliable,labor,quickly is an important factor to realize swing hang transport.The supporting leg of thesemi-trailer is the semi-trailer supporting device,which is installed on the left and rightsides of the front end of the frame of the semi-trailer truck,to realize the lifting andconnection of the tractor trailer and the semi-trailer,and ensure that the semi-trailer canindependently maintain stability after the tractor.It is one of the important parts of thesemi-trailer truck.The gear mechanism is used to complete the lifting of the semi-trailersupport device through the handle.Select the appropriate structural form to draw theassembly drawing of the supporting legs,select the suitable scheme to draw theengineering drawing of the relevant parts,and calculate and check the assembly drawingand the part engineering drawing.The design effectively solves the problems of time-consuming,laborious and poorsupport stability of the semi-trailer leg use,ensuring the safety and reliability of thesystem,clear function and working principle,and simple structure.Simplify thestructure and reduce costs.Semi-trailer has high reliability and easy maintenance.Key words:gear mechanism;semi-trailer;support leg assembly drawing;part diagram目录摘要Abstract .............III1.绪论.51.1课题背景.51.2国内外研究现状......51.2.1国内研究现状S1.2.2国外研究现状.......51.3未来发展趋势......….61.4研究的基本内容和拟解决的主要问题……61.4.1研究的基本内容61.4.2主要解决的问题..62.方案论证.……72.1支承装置的功用和要求.72.2支腿结构方案的确定......….72.3支承装置主要零件结构的方案论证93.支承装置各零件主要参数选择与计算.…...123.1直齿圆柱齿轮传动齿轮的设计计算......·.123.1.1选定齿轮类型、精度等级、材料及齿数123.1.2齿面接触强度计算....123.1.3计算接触疲劳许用应力..133.1.4齿根弯曲强度设计143.1.5设计计算........153.2直锥齿轮传动的设计计算及校核….153.2.1齿面接触强度设计..........。173.2.2校核齿根弯曲疲劳强度.................193.3底座参数的选择.......…..193.4内、外支撑壳体参数的选择..194.轴的结构设计计算.…214.1输入轴的设计计算.....214.1.1初步确定轴的最小直径214.1.2轴的轴向尺寸的确定214.1.3轴的径向尺寸的确定214.2输出轴的设计计算214.2.1确定轴各段直径和长度224.3螺杆的设计计算.....…225.校核........235.1轴的强度校核235.1.1输入轴。。。。。。。235.1.2输出轴25致谢.…28参考文献.…29W

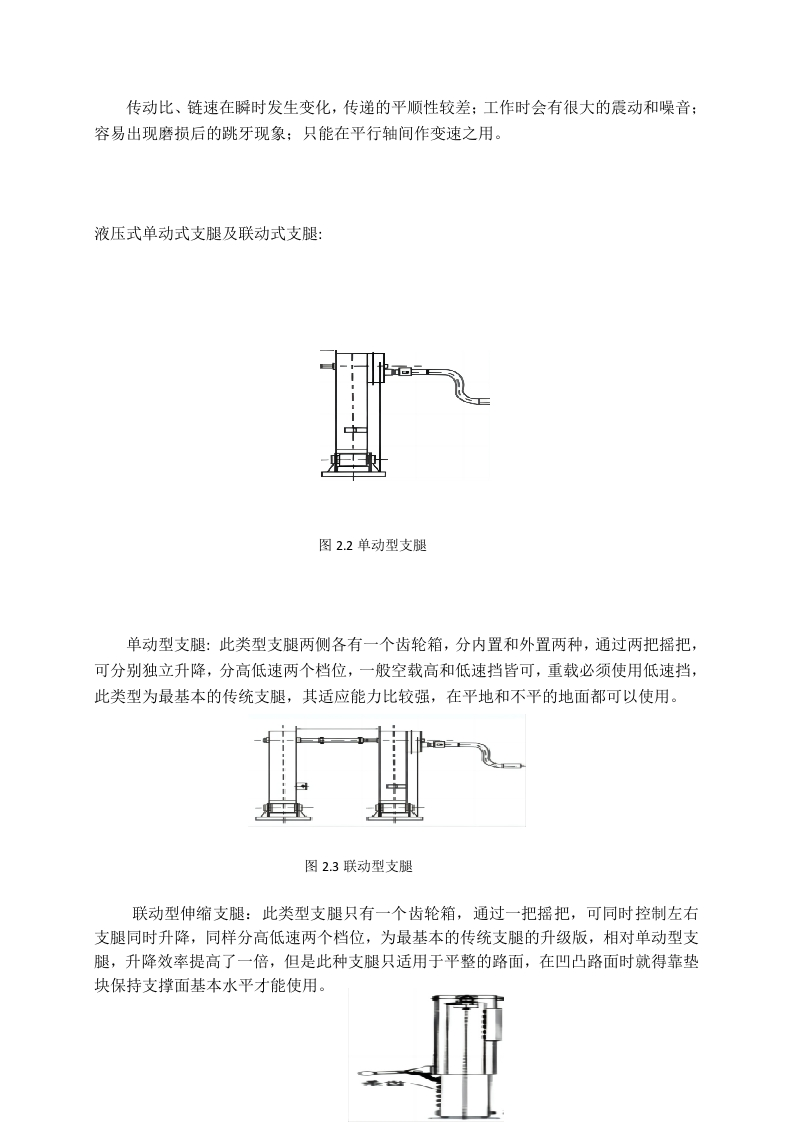

暂无评论内容