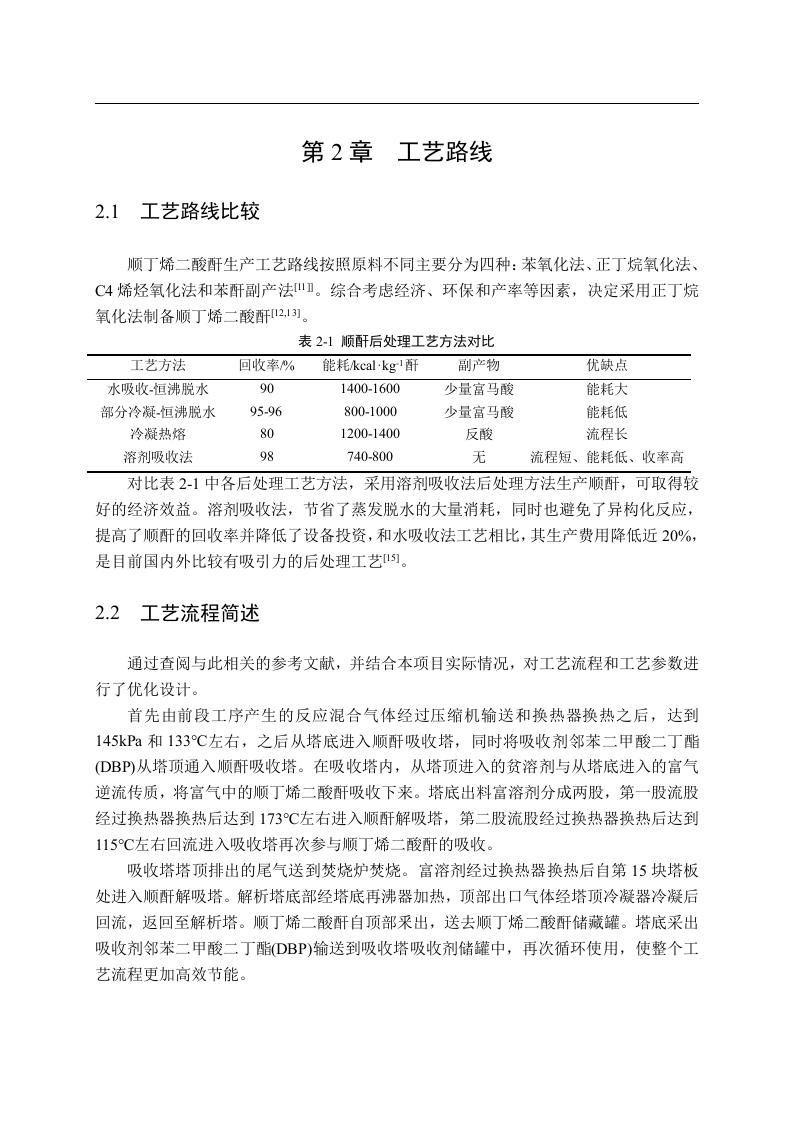

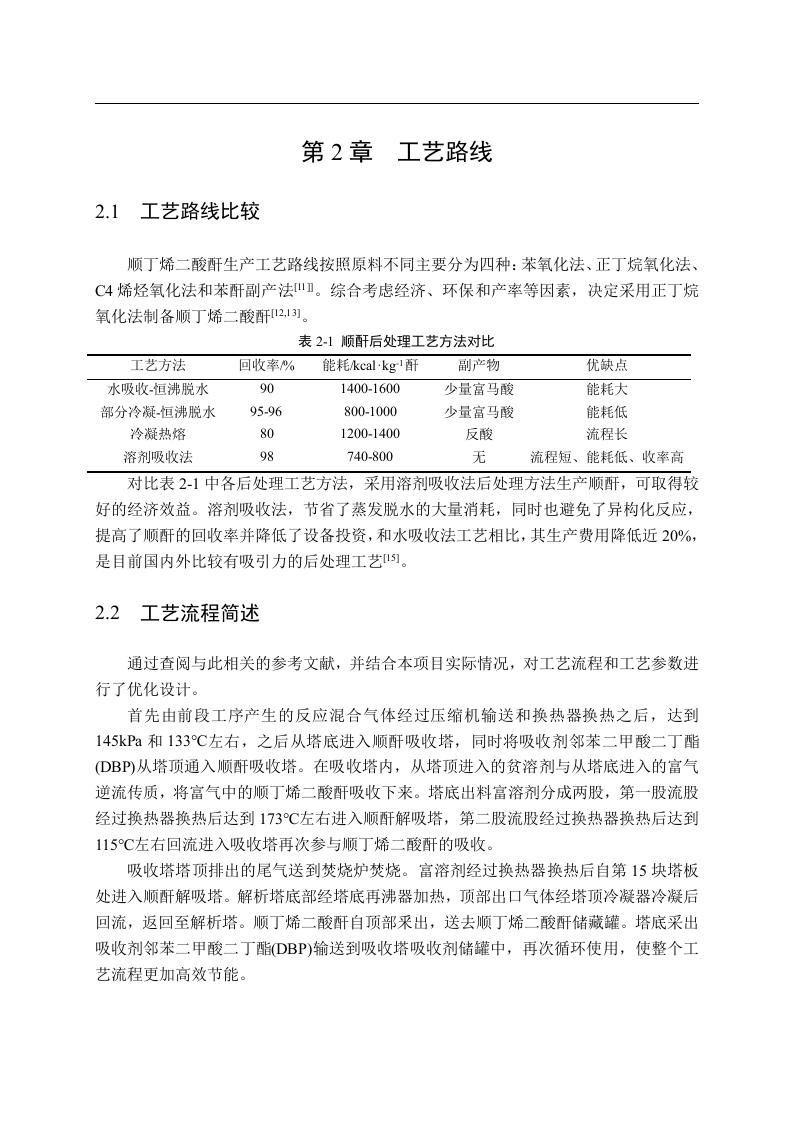

摘要本项目为正丁烷氧化法年产5万吨顺丁烯二酸酐吸收工段初步设计。首先,本文介绍了顺丁烯二酸酐的相关背景和用途、国内外发展现状、前景、生产方法及比较。其次阐述了课题的设计依据、厂址选择、设计规模、生产制度及产品规格。通过查阅资料对工艺进行比较确定工艺流程,进行物料衡算和热量衡算。利用软件对解析塔塔板数、进料板位置等变量进行优化,选取最合适的参数以达到同等产品规格下最低能耗的目的。通过设计结果对吸收塔、解析塔、换热器、泵和压缩机等主要设备进行设备选型。依据化工厂车间布置原则,完成对设备的平立面布置,并进行自动化控制、环境评估与安全评价和技术经济评价。最后利用AutoCAD绘制带控制点的工艺流程图、平立面布置图和主设备图,并完成设计说明书。关键词:顺丁烯二酸酐;模拟设计;工艺优化;Aspen plusAbstractThis project is the preliminary design of the absorption section for an annual production of50000 tons of maleic anhydride using the n-butane oxidation method.Firstly,this articleintroduces the relevant background and uses of maleic anhydride,the current developmentstatus,prospects,production methods,and comparison at home and abroad.Secondly,thedesign basis,site selection,design scale,production system,and product specifications of theproject were elaborated;Compare and determine the process flow by consulting materials,and perform material balance and heat balance calculations;Using software to optimizevariables such as the number of analytical tower plates and the position of feed plates,andselecting the most suitable parameters to achieve the lowest energy consumption under thesame product specifications;Select equipment for major equipment such as absorption tower,analytical tower,heat exchanger,pump,and compressor based on the design results.According to the layout principles of the chemical plant workshop,complete the horizontaland vertical layout of the equipment,and conduct automation control,environmentalassessment,safety evaluation,and technical and economic evaluation.Finally,use AutoCADto draw a process flow diagram with control points,a plan and elevation layout diagram,anda main equipment diagram,and complete the design manual.Key words:Maleic anhydride;Simulation Design;Process Optimization;Aspen Plus目录摘要Abstract…第1章绪论1.1概述…1.1.1选题的意义与作用.........111.2国内外研究现状1.1.3选题背景与设计内容.21.2设计依据21.3厂址选择.21.4设计规模与生产制度.31.5产品规格3第2章工艺路线..42.1工艺路线比较…2.2工艺流程简述4第3章工艺计算.63.1物料衡算63.1.1顺酐吸收塔T0101物料衡算….63.1.2顺酐解析塔T0102物料衡算..63.2热量衡算…73.2.2反应混合气换热器E0101热量衡算.73.2.2吸收剂预热换热器E0102热量衡算83.2.3吸收塔循环换热器E0103热量衡算.83.2.4解析塔进料换热器E0104热量衡算83.2.5顺丁烯二酸酐解析塔冷凝器E105、再沸器E106热量衡算83.2.6总公用工程.9第4章设备计算及选型.104.1吸收塔T0101计算及选型104.1.1参数优化.104.1.2塔内构件设计124.1.3壁厚及封头计算12

暂无评论内容