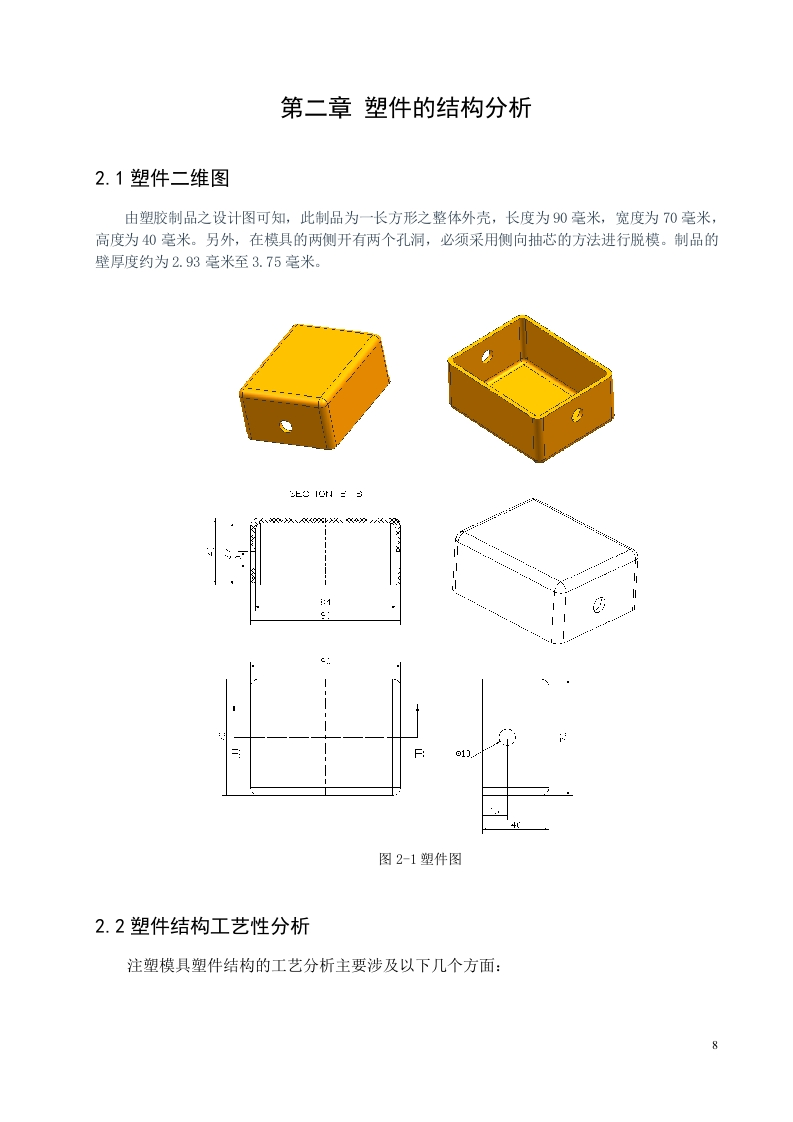

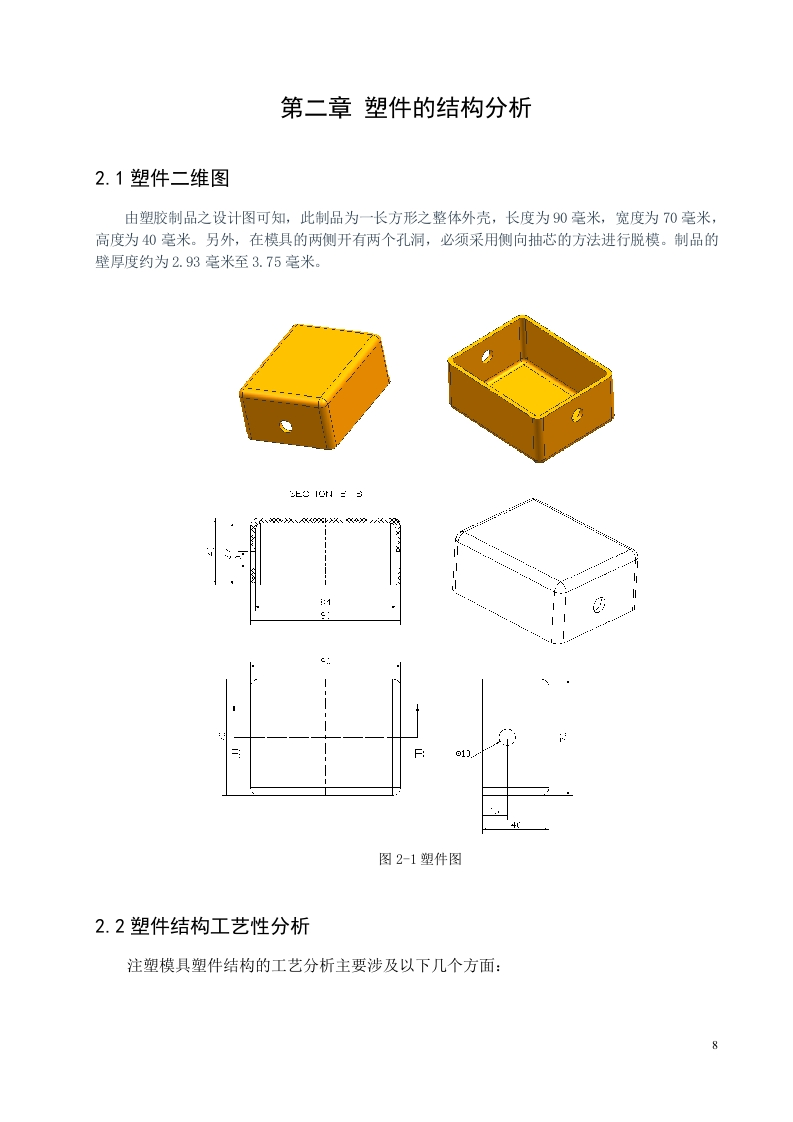

摘要本次毕业设计课题为双侧空方形箱体塑料零件注射模的设计。利用UG3D造型软件对该注塑制品进行了3D造型,并对其进行了初步的结构分析。经详细分析后,我们发现此注塑制品的内部构造及外部形状比较简单,是一种外壳型的零件,且壁厚均匀分布比较合理。综合考虑模具尺寸、生产效率等多种因素,确定了“一模两室两室”的型腔布局,以及“两板模”侧浇口的进料模式。注射模是一项新的生产产业,能够让塑料原材料成形,需对塑料零件的选材和成形过程进行分析,并确定注射成型机。在此基础上,选取了较为适宜的注射设备,对设备中的一些关键参数进行了检查与计算。另外,对注塑模具的分型面也进行了选取与设计。在对多组资料进行对比分析后,确定了最佳方案。在模具设计中,涉及到模具的分型面设计、浇注系统设计、浇注模式选择、主流道、分流道、浇口、冷腔的设计、模具关键零件的设计与尺寸计算等。通过对塑料模的型腔深度、型腔高度、型腔壁厚度、型芯高度等进行了计算与分析,确定了热风系统的设计与校核,确定了循环冷却水的冷却模式。同时,对注塑过程中的弹出机构、合模引导机构和其它辅助机构也进行了设计。通过对分支机构的一系列设计,确定了一模两型腔的塑模结构,并对各部分进行了CAD电子图纸的绘制。经过对CAD软件的应用,使我们对CAD软件的操作与应用有了更为全面的了解。关键词:模具设计:注射成型:塑件工艺分析:塑料模具AbstractThe topic of this graduation project is the injection mold design of a double-sided emptysquare box plastic part.We use UG 3D modeling software to design the 3D structure of thisplastic component and conduct original structural analysis.Through detailed analysis,wefound that the internal structure and appearance of this plastic component are relatively simple,resembling a shell component,and the average distribution of wall thickness is relativelyreasonable.Considering many factors such as die size and production efficiency,we finallyadopted the cavity distribution scheme of the first mock examination with two cavities,andadopted the side gate feeding mode of two plate dies.Injection molding is a new type of production industry that allows plastic raw materialsto be formed.It is necessary to analyze the material selection and molding process of plasticparts and determine the injection molding machine.For this reason,we have selected a moresuitable injection molding machine and verified and calculated several important parameters.In addition,we have also selected and designed the parting surface of the plastic moldIn mold design,we need to design multiple aspects of the mold,including the design ofthe mold parting surface,the design of the mold pouring system,the selection of pouringmethods,the design of the main flow channel,diversion channel,gate and cold material hole,as well as the design and size calculation of important molding components of the mold.Weconducted a calculation and analysis of the cavity depth,height,wall thickness,and coreheight of plastic molds,and selected the design and verification of the high-temperaturesystem using a circulating water cooling method.We have also designed the mechanism ofthe plastic part ejection system,the mold closing guidance system,and other auxiliarymechanisms.After completing the design of a series of branches,the plastic mold structurewith the first mock examination and two cavities was finally determined,and all parts andassembly drawings were drawn into CAD electronic files.By using computer-aided designsoftware CAD,we have gained a more comprehensive understanding of CAD softwareoperation and usage skills.Key words:Mold Design;injection molding;Plastic Part Process Analysis;Plastic Mold目录猪论.21.1塑料简述...。61.2注塑模成型工艺...61.3注塑模具的现状与发展与课题的意义.,2第二章塑件的结构分析..2.1塑件二维图...2.2塑件结构工艺性分析..82.3塑件材料的成型工艺分析.....102.4塑件质量与体积分析.·.11第三

暂无评论内容