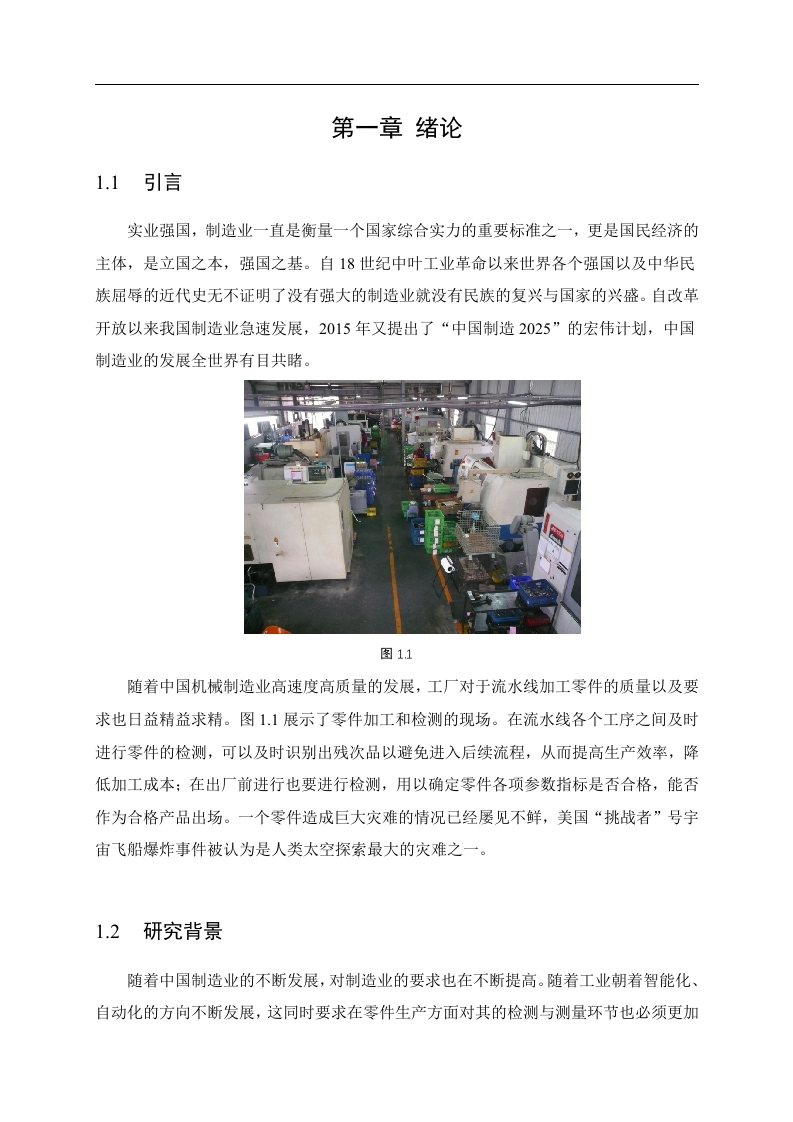

摘要尺寸测量作为工业流水线中有着至关重要的地位。在生产过程中不可避免会产生零件的缺陷与瑕疵,这时就可以通过对产品尺寸的测量来把控工件的质量以及及时区分出劣质与不合格产品。传统人工测量法精确度低、效率低,已不符合自动化工业流水线的要求。而机器视觉有着高效率、高精准度等特点,已在自动检测领域独占鳌头。本文主要研究的内容为基于机器视觉提供一套平台系统用于对工件尺寸进行识别。首先对图像的噪声及降噪进行研究,分析图像噪声类型以及对比不同滤波方法对不同种类噪声的降噪效果。然后就本次实验的具体图像的噪声类型提出一种自适应中值滤波器进行滤波。其次是边缘提取,本文基于Canny算子提出了一种优化的边缘提取算法。即将Canny算子中的高斯滤波依据主要使用场景改为中值滤波,以及基于局部的梯度确定高低阈值。在尺寸识别中还有一个重要的内容就是圆的识别。本文运用的原理是霍夫圆检测,在边缘识别之后用Sobl算子进行卷积,并沿梯度方向遍历边缘点,计算霍夫坐标系中相交的点并设定阈值,大于改阈值就将它认作为是圆。最后搭建了尺寸识别系统平台,并对实验数据进行分析,均能满足生产需求。关键词:机器视觉:尺寸测量:边缘提取:亚像素AbstractDimensional measurement has a crucial role in the industrial assembly line.Inevitably,defects and flaws in the production process will be generated,so the measurement of productdimensions can be used to control the quality of the workpiece and to distinguish betweeninferior and substandard products in a timely manner.The traditional manual measurementmethod has low accuracy and low efficiency,and no longer meets the requirements ofautomated industrial assembly lines.Machine vision,with its high efficiency and accuracy,has taken the lead in the field of automatic inspection.The main research of this paper is toprovide a platform system for workpiece size recognition based on machine vision.Firstly,the noise and noise reduction of the image are studied,and the types of imagenoise are analyzed as well as the noise reduction effect of different filtering methods ondifferent kinds of noise are compared.Then an adaptive median filter is proposed for filteringthe noise type of the specific image for this experiment.Next is edge extraction,and this paper proposes an optimized edge extraction algorithmbased on the Canny operator.The Gaussian filter in the Canny operator is changed to amedian filter based on the main usage scenario,and the high and low thresholds aredetermined based on the local gradient.Another important element in size recognition is the recognition of circles.In this paper,the principle of Hough circle detection is applied.After the edge recognition,the Sobeloperator is used to convolve and traverse the edge points along the gradient direction,calculate the intersecting points in the Hough coordinate system and set the threshold value,and recognize it as a circle if it is larger than the changed threshold value.Finally,the platform of size recognition system is built and the experimental data areanalyzed,all of which can meet the production requirements.Keywords:Machine vision;dimensional measurement;edge extraction;subpixel目录摘要Abstract..…目录第一章绪论1.1引言…1.2研究背景.1.3研究现状31.4论文结构.…4第二章尺寸测量系统框架设计及图像预处理62.1尺寸测量系统的框架设计.62.2图像的存储格式…72.2.1JPEG图像存储格式….72.2.2BMP图像存储格式」.82.3图像预处理….102.3.1图像降噪..102.3.2自适应中值滤波器..122.4本章小结..14第三章轮廓提取以及尺寸测量算子.153.1需求以及难点分析.…..153.2机器视觉测量方案...163.3改进的Canny边缘提取算法.173.3.1轮廓边缘检测.173.3.2边缘检测算子.193.3.3改进的Canny边缘提取算法.203.4圆识别算子….243.4.1霍夫直线变换.253.4.2霍夫圆变换26

暂无评论内容