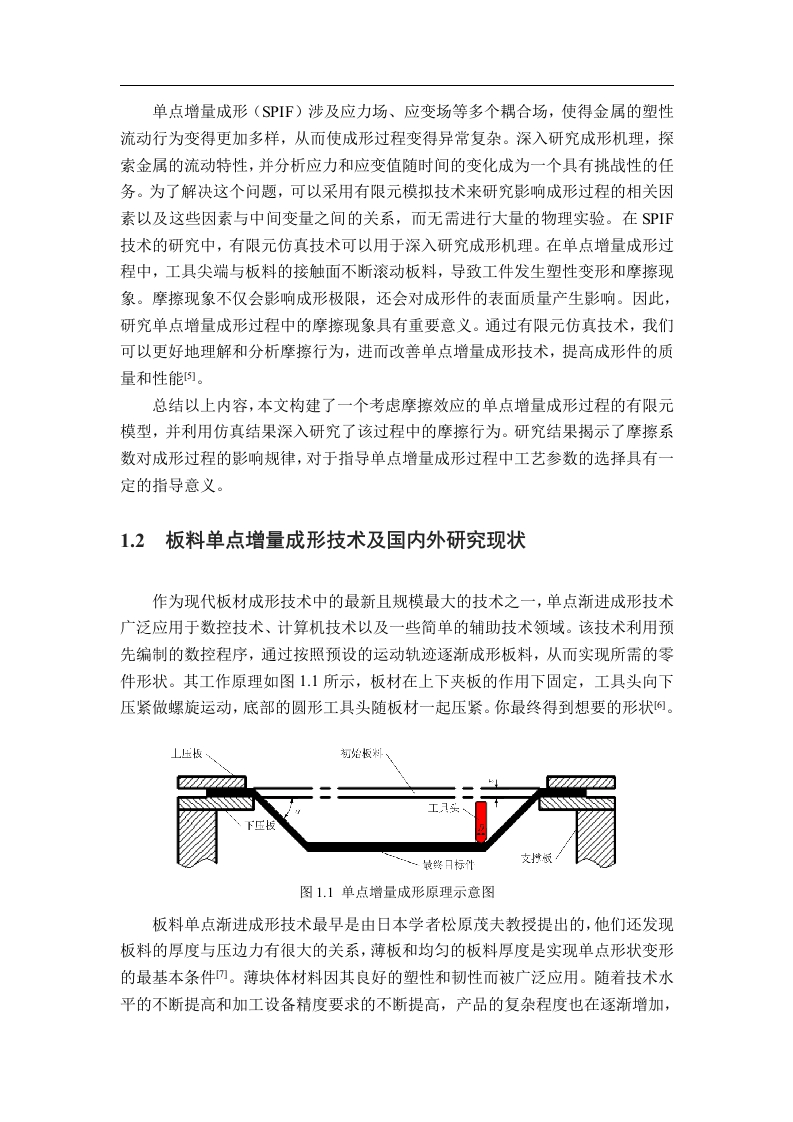

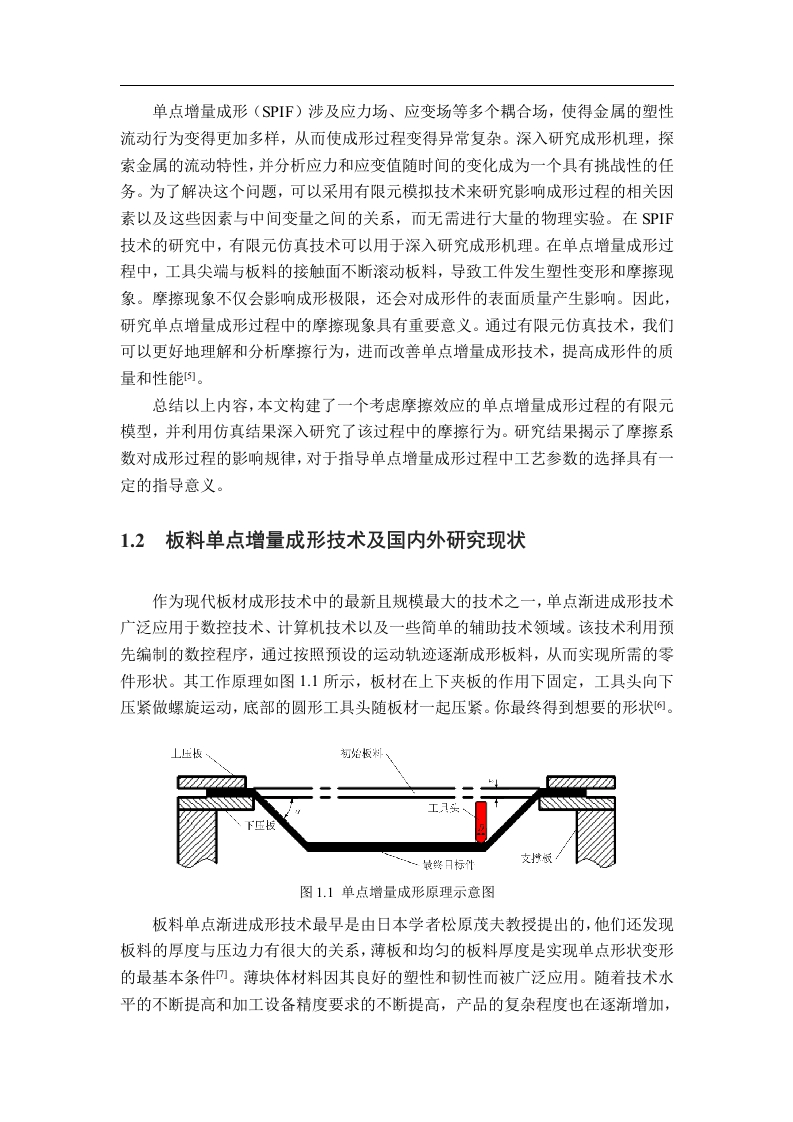

摘要单点增量成形是一种制造薄壁板料的快速成形方法,它通过局部逐层动态加载来加工板件材料。该技术具有成本低、速度快和无污染等优点,并能够制造传统工艺难以生产的复杂外形几何件。采用“分层制造”思想的单点增量成形技术主要是通过夹具将板料固定,然后使用圆形工具头逐层加工板料。在这个过程中,摩擦对金属的塑性流动和变形均匀性、成形力大小和表面质量等都会产生影响。为了研究不同单点增量成形工艺的摩擦行为,有必要研究原材料和工艺参数之间不同组合得到的摩擦系数如何影响成形过程。本文使用有限元仿真软件ABAQUS研究了单点增量成形中的摩擦行为。主要研究摩擦状态对板料的厚度、板料的位移变化、成形过程中工具头的受力变化的影响。结果表明,选择适当的工艺条件,可以有效地降低成形力和摩擦力。此外,摩擦行为对成形力、板料变形、等效应力和等效塑性应变都有显著的影响,选择合适的工艺参数能够得到较好的成形质量。这些发现对于优化单点逐步成形工艺参数以提高成形质量具有指导意义。关键词:单点增量;摩擦行为;有限元仿真;ABAQUSAbstractSingle-point incremental forming is a method of manufacturing sheet metal forrapid prototyping that uses partial dynamic loading to process sheet material in onestep.The technology has the advantages of low cost,speed,non-pollution,and theability to produce complex geometries that are difficult to produce with conventionalprocesses."The idea of "layered manufacturing"allows the single-point incrementalforming technique to be used mainly by holding the sheet in a fixture and thenmachining the sheet metal step by step with a circular tool head.In this process,thefrictional forces of plastic metal flow have an impact on forming forces anddeformation uniformity,dimensions and surface quality.To study the frictionalbehavior of the single-point incremental forming process,it is necessary to investigatethe important influence of the combination between raw materials and processparameters on the friction coefficient.This article uses the finite element simulation software ABAQUS to study thefriction behavior in single point incremental forming.The main research focuses onthe influence of friction state on the thickness of the sheet metal,the displacementchanges of the sheet metal,and the force changes of the tool head during the formingprocess.The results indicate that selecting appropriate process conditions caneffectively reduce the forming force and friction force.In addition,friction behaviorhas a significant impact on forming force,sheet deformation,equivalent stress,andequivalent plastic strain.Choosing appropriate process parameters can achieve goodforming quality.These findings have guiding significance for optimizing single pointprogressive forming process parameters to improve forming qualityKeyword:Single point increments;Frictional behavior;Finite elementsimulation;ABAQUS目录摘要1Abstract .......21绪论.0.51.1研究背景及意义..…51.2板料单点增量成形技术及国内外研究现状.........·61.3研究方法及内容......71.4本章小结.....82有限元技术...92.1有限元分析原理.……92.2 ABAQUS软件介绍......…92.3 ABAQUS基本模块...102.3.1 ABAQUS /standard....102.3.2 ABAQUS/,Explicit.................102.3.3 ABAQUS其他模块.........102.3.4 ABAQUS,/Explicit的在本文中的应用.......112.4本章小结.113建立单点增量成形有限元仿真模型133.1几何模型的建立......133.2材料参数.....143.3分析步153.4接触设置....153.5载荷及运动轨迹设置163.6网格划分173.7本章小结..……184单点增量成形过程有限元结果分析...194.1金属板单点增量成形过程中板料的厚度变化.....…194.2金属板单点增量成形过程中板料的位移变化......·204.3金属板单点增量成形过程中工具头的受力变化..224.4金属板单点增量成形过程中能量变化规律...·23

暂无评论内容