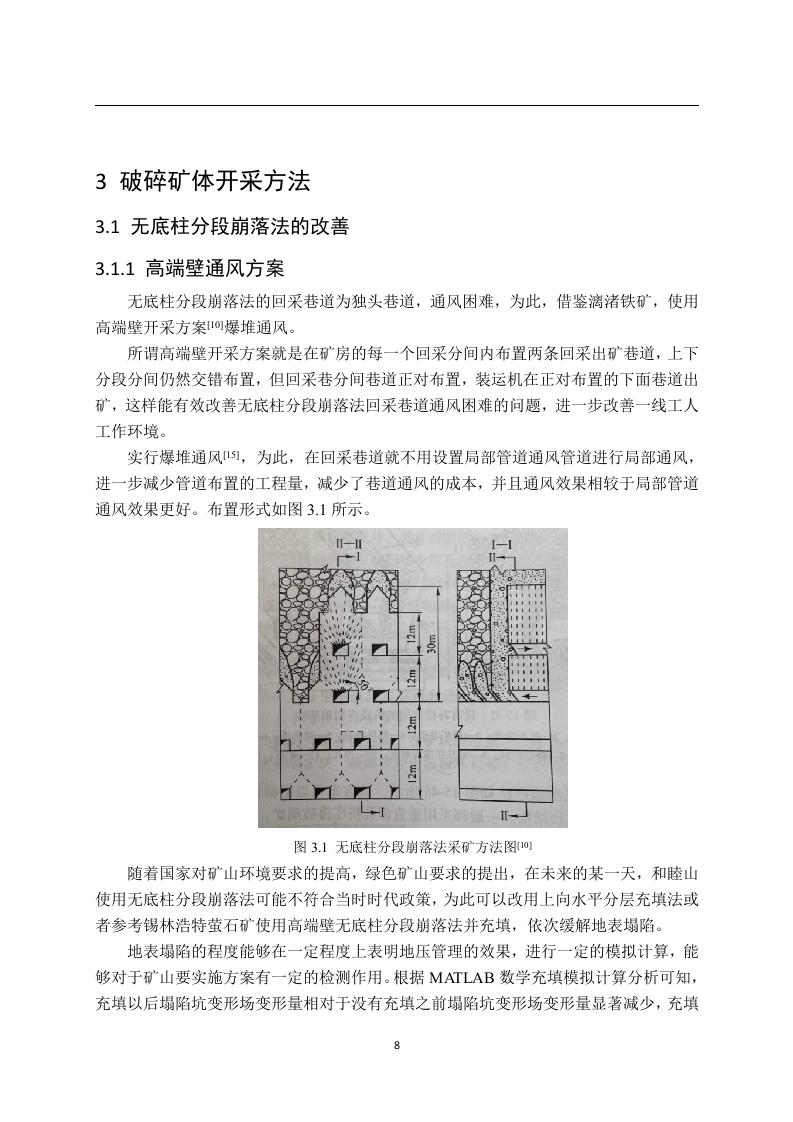

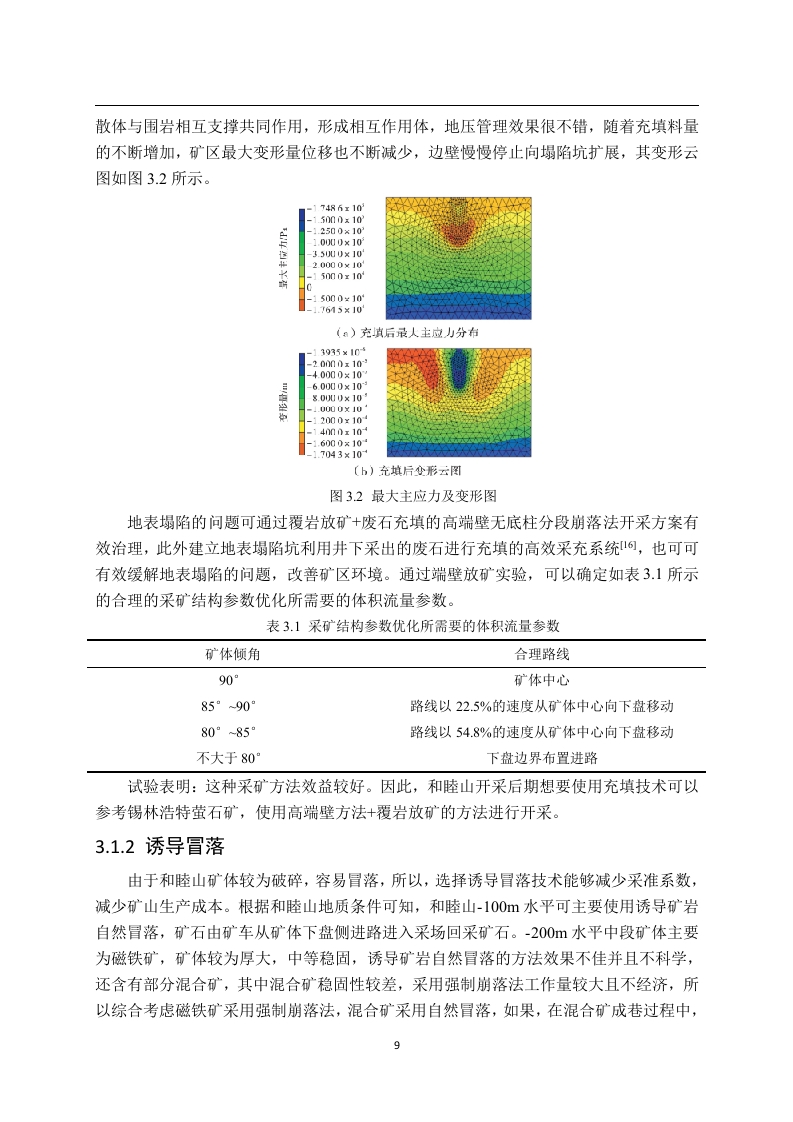

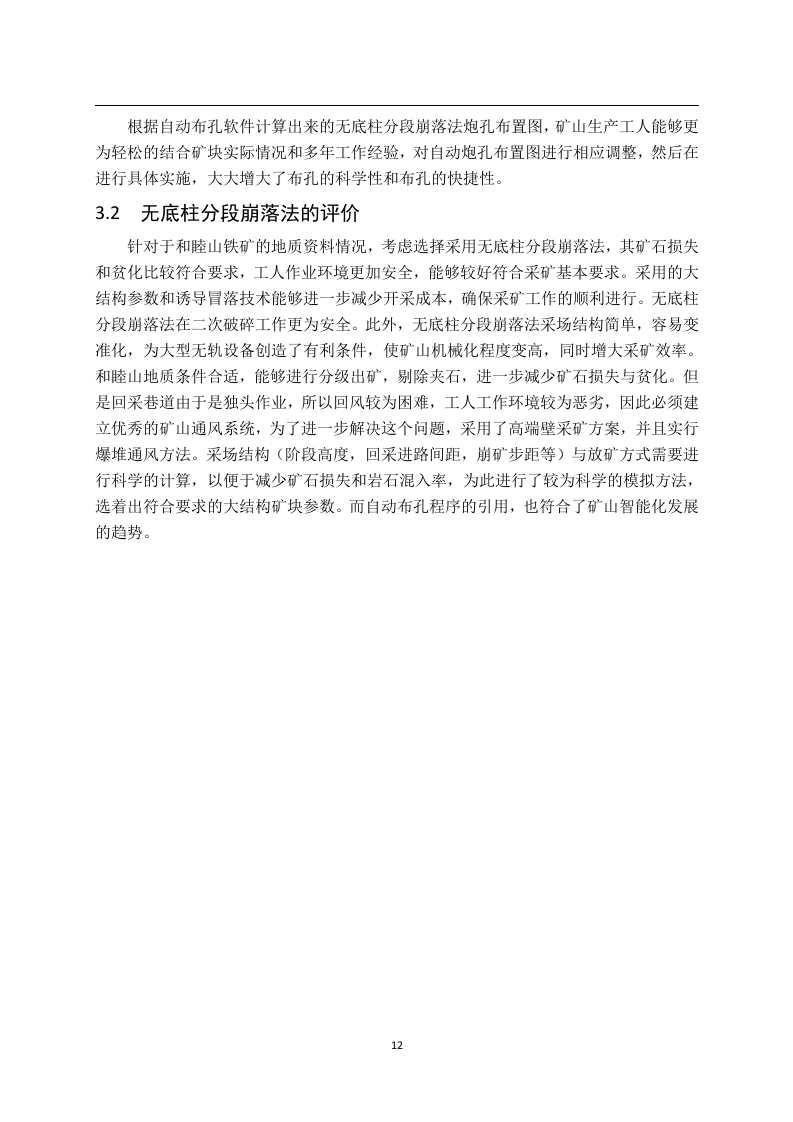

AbstractAs an efficient mining method for underground mining,sublevel caving without sillpillar has been applied in a large number of mines at home and abroad.However,with thedifferent mining conditions,sublevel caving without sill pillar has been continuously adaptedand improved.Since the application of pillarless sublevel caving method,mine designers havecontinuously improved it in order to make its mining effect better.Hemuushan iron mine s abroken and difficult to mine ore body.Its design and application can be used as a practicalreference for other mines.The ore body of Hemushan iron mine is relatively broken,withpoor ore stability.The geological conditions of the upper and lower walls of the ore body aregood,relatively solid and stable.After comprehensive reference to the geological conditionsof Hemushan ore body and consideration,it is considered that the sublevel caving methodwithout bottom pillar and upward layered drift filling method are better methods for miningand muchan broken ore body.Therefore,after the scientific comparison of the two methods,amore suitable mining method is selected for ore mining in harmony mountain.Aftercomprehensively evaluating the mining and cutting ratio of 1000 tons,the geological outputof ore block,the ore loss rate,the mixing rate of waste rock and the annual output of oreblock,it is considered that the bottomless pillar sublevel caving method is more suitable forthe geological conditions of Hexian mountain and can produce better benefits.The bottomlesspillar sublevel caving method is optimized to make it more in line with the geologicalconditions of Hemushan iron mine and increase its mining efficiency.The method of inducing caving with large structural parameters is adopted to reduce themining and cutting ratio of 1000 tons and reduce the investment cost of the mine.Theautomatic hole layout program of pillarless sublevel caving method is used to arrange theblast holes in Hemushan iron mine,so as to improve the degree of automation.The high-endwall scheme is adopted to improve the ventilation of the mining roadway,so as to improve thedifficult ventilation of the mining roadway in the sublevel caving method without bottompillar,further optimize the working environment of workers and create the safest and greenworking environment for mine workers.According to the design requirements,this design is an underground mining design withan annual output of 600000 tons of iron ore.The main mining objects in this design are the

项目总承包管理组织方案-c9a0040014-docx-1.webp)

暂无评论内容